In the last few decades, Computer Numerical Control (CNC) CNC machining has revolutionized many aspects of manufacturing and engineering. CNC Machining is a process which combines digital technology with traditional machining to create high-precision components across a range of industries. This article explores the mechanics, advantages and numerous applications of CNC machine machining, and highlights the impact it has had on the field of modern engineering.

The mechanisms of CNC Machining

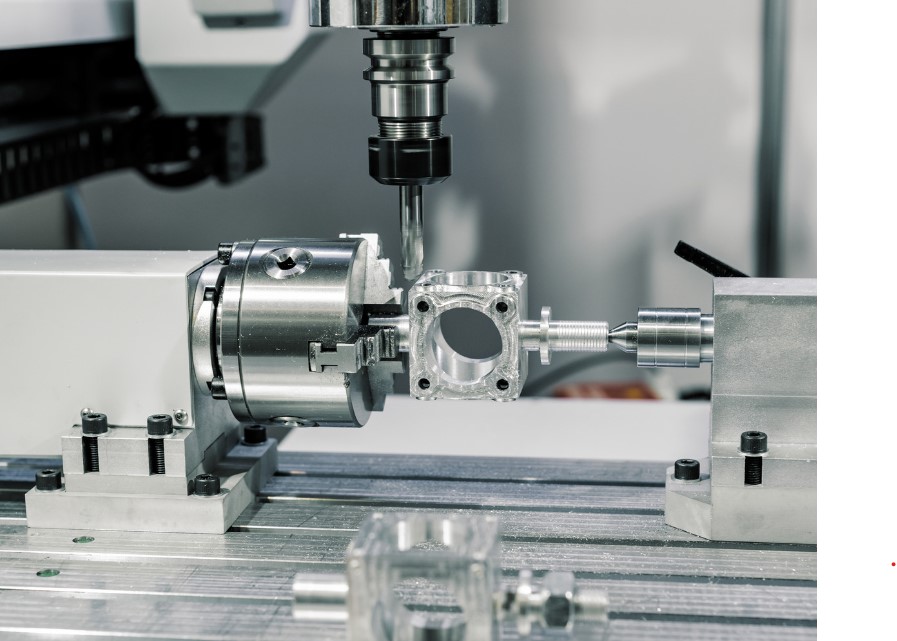

CNC machining is a subtractive method of manufacturing that removes material from a block of solid material, or workpiece, in order to form the desired shape. This process is guided by computer programs that regulates the actions of the machinery. The code generated for CNC machines differs depending on the specific model of machine as well as the complexity of the item being made. However, the fundamental principle is the exact the same: a high-speed cutter cuts material carefully in order to make the finished product.

Precision is the main benefit of CNC processing. Digitalization can ensure extremely precise and consistent production. This minimizes human error and guarantees consistency between batches. This quality of accuracy is crucial in fields where even slightest deviation can have major effects, including medical devices, aerospace manufacturing, and automotive.

The role of digital computers in CNC machine operation

The integration of digital technology is the foundation of CNC machining’s efficiency and accuracy. The software that is specifically designed for CNC machining automates all manufacturing processes. This software converts computer-aided design (CAD) models into a series of precise instructions, which the CNC machine then follows to create the part. The instructions are able to dictate every aspect of the process, from the direction and speed of the cutting tool, to the depth and angle of each cut.

In large industrial plants computers are often connected directly to CNC machines. This lets for seamless communication and controls. This integration enables real-time monitoring and adjustments, ensuring maximum performance while reducing time to repair. The automated nature of CNC machining also allows for continuous operation, greatly increasing efficiency and reducing time to market.

CNC Machining: Its Advantages

CNC machining has numerous advantages over other methods of manufacturing. Its capability to make intricate and complex components with high precision is just one of its most important advantages. The accuracy of CNC machines eliminates the requirement for manual adjustments and the need for rework, decreasing waste and increasing efficiency. CNC machines also operate continuously and are ideal for production runs that are large.

CNC machineries have another benefit it’s versatility. One machine can make various types of components just by changing the programming. This versatility is what makes CNC machining suitable for both prototyping as well as mass production, allowing manufacturers to react quickly to changes in market demand.

The process of automating CNC machines also increases security in the workplace. The risk of injury and accidents is reduced by reduction of manual intervention. CNC-machined components are also more durable and perform better, thereby increasing satisfaction of customers.

CNC Machining Services: Benefits to Industries

The flexibility, precision and effectiveness of CNC machining are used in many industries. CNC machines are used in the aerospace industry to create essential components that have to meet stringent safety and performance standards. CNC machines are used in the medical device sector to manufacture intricate surgical implants and instruments. Precision is of paramount importance.

CNC machineries can be utilized to produce engine parts including transmissions, intricate inside and exterior components, and even intricate exterior and interior designs for the automotive industry. Electronics industry also benefit from CNC machineries, which are able to produce tiny, intricate parts for consumer electronics and communications devices. In addition, the art and jewelry industries utilize CNC technology to produce intricate designs and custom-made pieces.

The future of CNC Machining

CNC capabilities in machining are predicted to grow as technology advances. CNC’s capabilities will be further developed by new technologies like multi-axis machines additive manufacturing, advanced materials. Machine learning and artificial intelligence will likely improve the precision and efficiency of CNC machining.

In the end, CNC machining has profoundly affected modern manufacturing and engineering, offering unparalleled precision, efficiency and versatility. The capability to make high-quality, complex parts can make CNC machining an indispensable tool in many industries. CNC manufacturing, as the technology advances, will continue to be an integral component in manufacturing’s future.