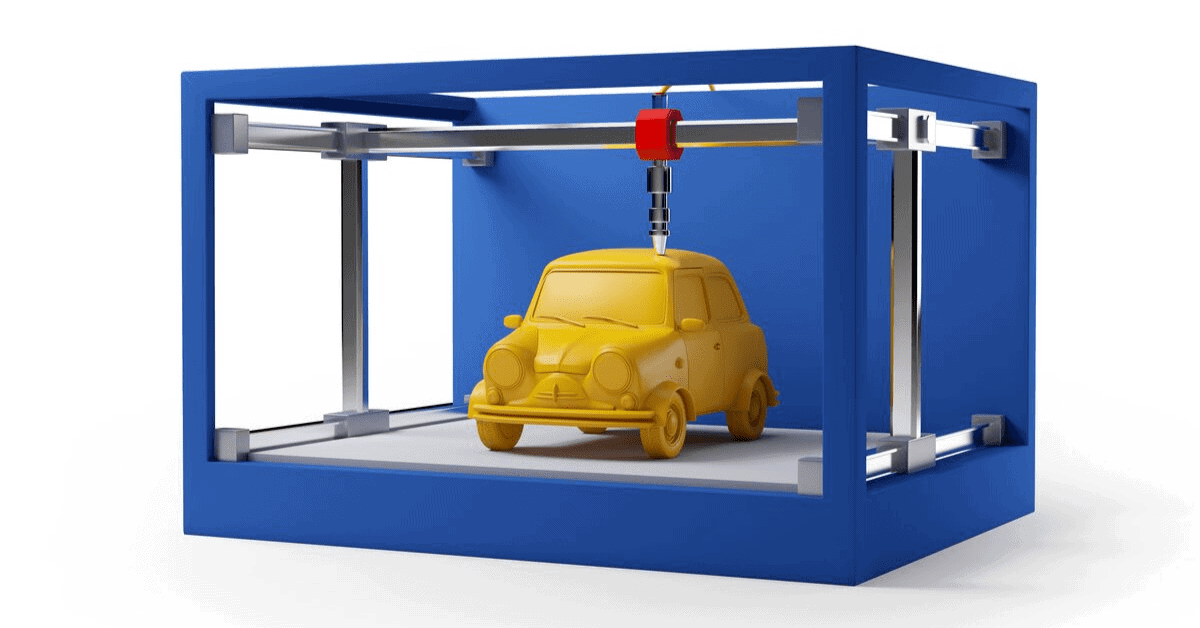

3D printers will be the next generation of manufacturing. They’re getting better and better every day. They can be utilized to make any item you want such as cases for your tablet, phone or furniture, or figurines which can be used as gifts, or even musical instruments. These machines offer endless possibilities, but before you get going, there are a few things to learn.

Uses and types of 3D printers

3D printers have become an emerging technology in recent times. This is because they can produce physical objects with great precision and detail, making ideal for architects that need to create models, or designers trying to imagine how different materials would look in their designs before creating them! FDM is also known as “Fused Deposition Modeling”, is a 3D printing machine which is more efficient than the others. It is able to heat plastics until the shape you desire. It means that you don’t need to spend long hours playing with different shapes. You can choose from pre-programmed options like taco shells or c payer boxes.

Printers that are custom-built

It’s an important decision whether to buy a pre-assembled 3D Printer or build it by yourself. Are you able to commit time? Are the skills required to construct a home difficult or impossible to acquire? This may be of interest to you. If so, look into purchasing parts compatible with an individual who understands exactly what they require prior to heading out to stores yourself.

Price

The 3D printer is a revolutionary technology that can create three-dimensional items using either plastic or metal. These printers can cost anything between $1000 and 2000 dollars depending on their quality. We suggest starting with a lesser-cost option such as a gyro-drone kit that is priced at just 100dollars.

Materials

3D printing is a revolutionary improvement in the field of manufacturing. It allows for intricate objects to be created with amazing detail. Today, we’ll look at two of the most popular kinds of materials being used at this process: Acrylonitrile Butadiene Styrene and Poly Lactic acid both become extremely soft after heating, however they become hard once cool however, there are some important aspects you need to take into consideration before making your final decision! Certain printers work best with one type of material. So be sure to choose the right type.

Safety

3D printers are fantastic tools that can be used to do all sorts of things from replicating human organs to creating useful objects. But, they also emit some fumes which may not only make you sick however, they can also harm or kill someone else if their eyesight is delicate enough (for example kids). To ensure the safety of everyone involved, I recommend that you use a high-quality , high-quality eye mask to operate one.

Quality

With the aid of a top printer you can create high quality printed products. Two aspects to take into consideration print speed and quality. The printer’s resolution is measured in microns. Lower numbers mean higher quality prints. The speed at which your machine moves ink around could affect the speed an object gets completed printing. Thus, you must ensure that your front line machine has the capacity to handle the smallest of moments.

For more information, click high-temperature 3D printer